เป็นเจ้าของธุรกิจง่ายๆ หากคุณอยากจะก้าวเข้าสู่การเป็นเจ้าของแบรนด์ตัวจริงโดยไม่ต้องลงทุนสร้างโรงงานผลิตเอง เรามีบริการ OEM ซึ่งเป็นโรงงานรับผลิตแบรนด์ของคุณแบบครบวงจรเหมาะสำหรับของเจ้าของแบรนด์ในยุค 4.0 เพระาเราไม่ได้รับเพียงแค่การผลิตสินค้าให้คุณอย่างเดียวเท่านั้น แต่ยังมีอ๊อบชั่นเสริมต่างๆ เพื่อช่วยเหลือเจ้าของแบรนด์ให้สามารถก้าวผ่านปัญหาเรื่องผลิตภัณฑ์ได้อย่างยั่งยืน

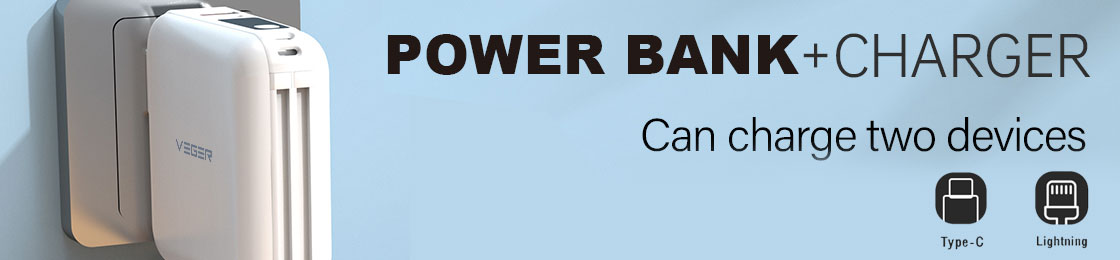

รับผลิตแบตเตอรี่สำรอง ชุดหูฟัง หัวชาร์จ สายชาร์จ รับผลิตปลั๊กไฟ รับสร้างแบรนด์แบบครบวงจร ภายใต้แบรนด์ของท่าน สินค้ากว่าร้อยแบบ เลือกผลิตได้ตามความต้องการโดยผลิตตามมาตรฐานของเครื่องหมาย มอก.รับประกัน บริการด้วยความมุ่งมั่นและจริงใจ ด้วยต้นทุนที่คุณสามารถกำหนดได้ บริการแบบ One Stop Sevice ที่มีคุณภาพ การออกแบบบรรจุภัณฑ์ ฉลาก พิมพ์กล่อง ส่งมอบสินค้าใน 30 วัน รับประกัน 365 วัน สามารถมีสินค้าออกสู่ตลาดได้ทันที เพื่อตอบสนองความต้องการของลูกค้าอย่างสะดวกรวดเร็วและเกิดความพึงพอใจสูงสุด